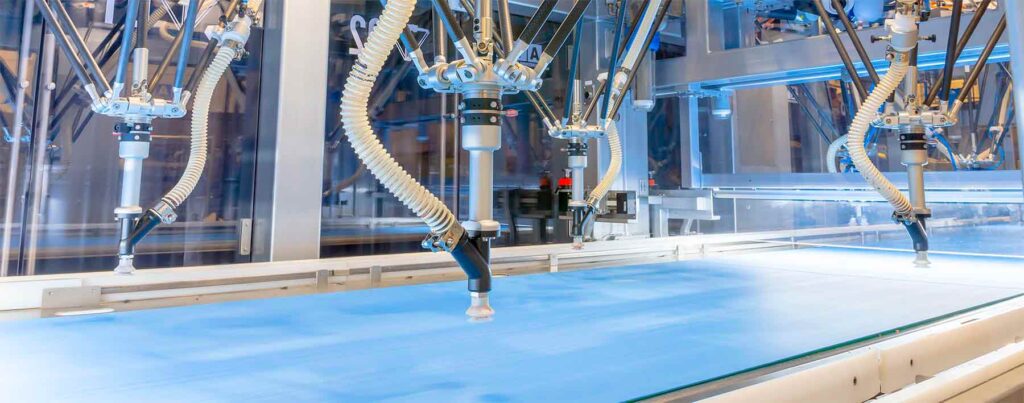

In the competitive world of manufacturing, both food and non-food sectors are constantly seeking ways to stay ahead. One proven method is through packaging automation, specifically the robotization of primary or secondary packaging lines. ATP Packaging, a leader in this field, offers solutions that not only increase productivity but also provide a host of other benefits.

The Impact of Packaging Line Automation on Productivity and Quality

Packaging line automation, particularly through robotics, significantly enhances productivity. It addresses the challenge of labor shortages and the pressure on the workforce, making it an essential solution in today’s manufacturing environment.

ATP Packaging’s robotized lines offer flexibility and adaptability across a wide range of sectors. Post-installation, manufacturers often report a noticeable reduction in poor quality or rejected products. The return on investment is also attractive, as automation reduces labor costs associated with low-value tasks.

The Benefits of Packaging Automation: A Closer Look

Robotizing your primary or secondary packaging line offers several advantages. Here are some reasons why you should consider implementing packaging automation:

Increased Productivity

Robots can work at a faster pace compared to manual labor, resulting in increased production rates. They can perform repetitive tasks with high precision and consistency, reducing the likelihood of errors and improving overall efficiency.

Cost Reduction

Packaging automation can significantly reduce labor costs associated with repetitive and low-value tasks. Robots can work continuously in a 3×8 shift pattern without the need for breaks, vacations, or overtime pay. This allows you to optimize your workforce and allocate human resources to more complex and rewarding tasks.

Improved Quality Control

Robotized packaging lines offer enhanced quality control capabilities. They can perform inspections and checks with great accuracy, minimizing the risk of poor-quality products reaching the market. This helps to maintain customer satisfaction.

Flexibility and Adaptability

Robotized packaging lines can be programmed and easily adapted to different product sizes, shapes, and packaging formats. ATP Packaging’s automated solutions can handle a wide range of applications across various industries, providing the flexibility needed to meet changing market demands and customer requirements.

Quick Changeover

Changing packaging formats or product variations can be time-consuming and costly. Robotic packaging systems, like those offered by ATP Packaging, are designed to facilitate fast changeover. Digital motors manage case pitch, case width, and other parameters, while automatic tooling systems simplify the process of changing robot tooling. This minimizes downtime and allows for rapid transition between different packaging requirements.

Improved Working Conditions

By automating repetitive and physically demanding tasks, robotization helps to improve the working conditions for operators. It eliminates the risk of musculoskeletal disorders associated with manual labor, allowing workers to focus on more rewarding and intellectually stimulating tasks, such as machine programming, monitoring, and maintenance.

Data Collection and Analysis

ATP Packaging’s machinery is equipped with sensors and data collection capabilities. This allows manufacturers to gather real-time information about the packaging process, such as production rates and downtime. By analyzing this data, companies can identify areas for improvement, optimize efficiency, and make data-driven decisions to improve their packaging operations.

In summary, packaging automation, particularly the robotization of your primary or secondary packaging line, brings numerous benefits. These include increased productivity, cost reduction, improved quality control, flexibility, quick changeover, enhanced working conditions, and the ability to innovate and stay competitive in the market.