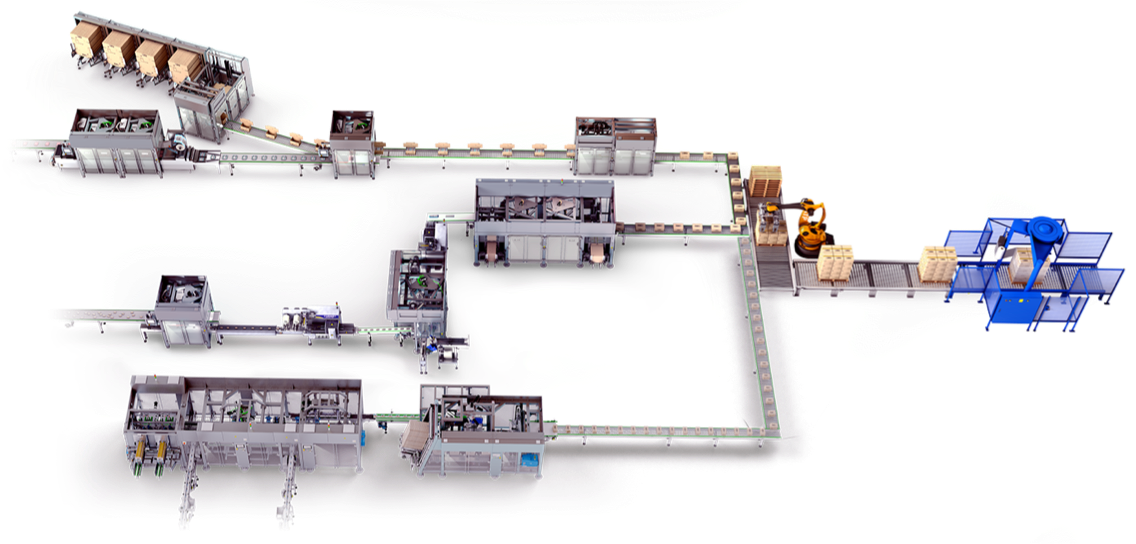

Complete Packaging Lines

At ATP Packaging, we supply complete packaging lines for the automatic packaging of primary or secondary products, from the time the product exits the production process to its palletizing, including automatic picking, cartoning and case packing.

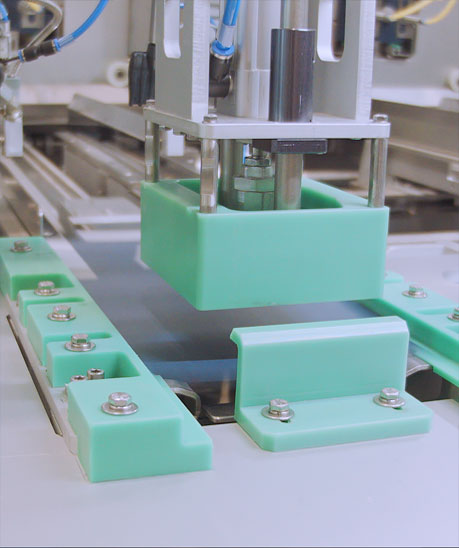

We have more than 25 years of experience, which allows us to adapt to different technologies according to the characteristics of the application, to achieve maximum flexibility and efficiency, and to be able to offer remote assistance services. We have packaging lines with robots guided by artificial vision for the collection of the bare product and lines for the cartoning and case packing of the packaged product.

Our Machines

Great flexibility

Allowing you to work with different products and packaging formats, increasing the flexibility and competitiveness of the production process.

Safety and hygiene

There is no manual contact with the product and repetitive tasks that cause occupational accidents and do not add value to the process are eliminated.

Open platform philosophy

Facilitates all maintenance and repair functions by the end user and provides great versatility in choosing the vision system that best suits the needs of the process.

Discover which elements can make up a packaging line

Delta robots guided by artificial vision

Grouping and accumulation systems

Product quality control systems

Plastic or cardboard tray dispensers

Transport logistics of products and packages

FIFO and LIFO accumulation buffer

Horizontal flow wrappers and vertical packaging equipment

Palletizing with collaborative or conventional robot

Case erectors and sealers and top-load case packing

Top-load and side-load carton erectors and sealers

Multi-format wrap around case packers

Discover our full range of packaging machines

Frequently Asked Questions (FAQ) about our Packaging Lines

What distinguishes the packaging lines offered by ATP Packaging?

Our packaging lines are designed with cutting-edge technologies that guarantee efficiency and precision in the packaging process. These solutions cover a wide range of applications in multiple sectors, from food to pharmaceutical, ensuring that products are packaged safely and efficiently.

What are the main sectors that can benefit from our packaging lines?

We offer specialized solutions for a wide variety of industries including food, pharmaceutical, hygiene, cosmetics and home care, among others.

Each line is designed to meet the specific needs of each industry, guaranteeing optimized and bespoke solutions.

What type of technology do we incorporate?

Our lines use advanced technologies, from robotic systems to state-of-the-art machinery, which guarantee fast, precise and high-quality packaging. This investment in technology allows us to be at the forefront and develop applications that anticipate the needs of the market.

Do we offer customized solutions for packaging lines?

Absolutely. We understand that each client and sector has specific needs. Therefore, we offer the possibility of engineering and personalizing our packaging solutions to meet individual demands, thus guaranteeing a machine that perfectly fits each requirement.

In terms of quality, what guarantees do you offer?

Quality is a priority for us. We are committed to offering packaging solutions that meet the highest industrial standards. In addition, our team of professionals constantly works to ensure that each process, from design to production, is carried out with maximum precision and efficiency.

How can you increase the productivity of packaging lines in a company?

To increase the productivity of packaging lines in a company, it is essential to adopt a combination of technological and operational strategies.

Firstly, investing in packaging machinery and cutting-edge technology improves the speed and precision of the packaging process. Automation reduces downtime and minimizes human error.

Additionally, ongoing staff training ensures they are familiar with best practices and can operate machinery efficiently. It is equally crucial to conduct regular workflow analysis to identify and eliminate bottlenecks. Implementing a quality management system can help monitor and continually improve process efficiency.

Finally, maintaining open communication with suppliers and customers allows you to quickly adapt to changing market demands and optimize the supply chain.