1. Introduction to packaging machinery

Packaging is a fundamental part of the production and distribution process of any product. This process not only ensures that the products are protected, but also facilitates their storage, transport, and plays a crucial role in the marketing strategy and promotion of the brand. Given its relevance, it is essential to have efficient and reliable packaging machinery that meets the expectations and needs of the industry.

2. Description and operation of packaging machinery

Packaging machinery refers to the set of mechanical devices that are used to pack and package products throughout a production chain. This equipment is designed to work systematically and precisely, efficiently creating, arranging, and placing items within the package.

In addition to their practical function, these machines are a guarantee of quality and an important part of marketing strategies. They ensure that products reach the customer in perfect condition, and help strengthen the brand image by providing well-designed and attractive packaging.

3. Packaging machinery and quality guarantee

Good packaging is the result of quality packaging machinery. Quality packaging protects the product from damage, moisture, and dirt, and ensures that it reaches the customer in perfect condition. It also contributes to building trust in the manufacturer, since it ensures that the products have not been tampered with after manufacture and have been preserved in excellent conditions within their packaging.

For the manufacturer, optimal packaging also has important benefits. It guarantees that the products will reach the customer in good condition, which is essential for good reviews and a positive reputation. Furthermore, well-designed packaging can become a powerful marketing tool, as it can help to highlight the product and brand.

4. Packaging machinery and brand image

Product packaging is often the first thing a customer sees, so it can have a big impact on brand perception. Good packaging design can help convey brand values, capture customer attention, and differentiate your product from the competition. Therefore, the use of quality packaging machinery is crucial to maintaining and improving brand image.

5. Keys of the packaging machinery industry

Packaging has evolved enormously throughout history. From the first leather, clay, or metal containers used to preserve food, to the appearance of the bottle in the 17th century and the packaging revolution brought about by the Industrial Revolution in the 18th century, with the creation of the first automated production lines. and cardboard packages.

Today, packaging not only protects and facilitates the transport of products but also provides important information for customers and is a powerful marketing tool. Creative designs, eye-catching colors, and original slogans can attract consumers and differentiate products from the competition.

6. Types of packaging machines

There are several types of packaging machinery, each with specific characteristics and uses. The most common ones are listed below:

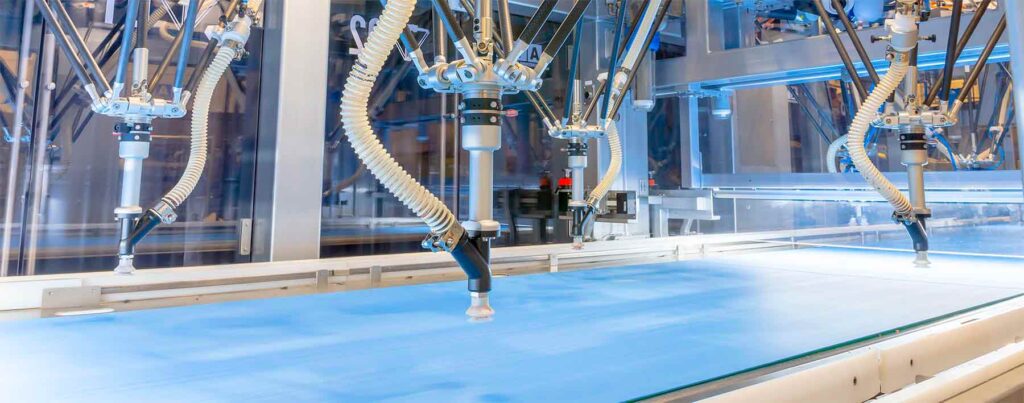

6.1. Pick & Place Robots

Pick & Place robots are automated systems used to pick and place products into packaging machines. There robots can be programmed to perform specific tasks such as feeding flowpacks, loading blisters, trays, cartons or cases.

6.2. Cartoners

Cartoners, as their name suggests, are machines that place products in cartons.

6.3. Case packers

Case packers are machines used to pack products into transport or display cases for storage and transportation.

6.4. Case erectors

Case erectors are machines used to form cases from flat cardboard blanks.

6.5. Case Closers

Case closers are machines used to seal cases after they have been filled with products. This type of machine is essential to ensure that products remain safe during transport and storage.

6.6. Flow Packs

Flow Pack machines are a type of horizontal packaging machine primarily used in the food industry. These machines wrap the product in a plastic film or eco-sustainable materials, forming a hermetically sealed package that protects the product and extends its shelf life.

6.7. Carton Erectors

Carton erectors are machines used to form cartons or trays from flat blanks. These machines provide a solution for companies to adopt more sustainable practices and promote the reduction of plastic usage in packaging.

6.8. Carton Closers

Carton closers are machines used to seal cartons containing products. These machines are an essential part of the packaging process, as they ensure the protection and preservation of products during transportation.

7. Automated packaging machines: are they the best option?

Automated packaging machines offer many benefits. First of all, they can work faster and more accurately, eliminating bottlenecks in the production chain. Second, they can operate 24/7, resulting in greater productivity and flexibility.

In addition, automated machines minimize the risk of accidents, since they eliminate the need for human intervention in certain potentially dangerous tasks. They also decrease the chances of human error, which leads to product loss.

Finally, automated machines are an investment that reduces costs in the medium and long term. Although the initial cost may be higher than manual machines, time savings, and efficiency will quickly return the investment.

8. Considerations when selecting packaging machinery

There are a number of factors to consider when selecting packaging machinery. These include:

Type of product

Some machines may not be suitable for certain types of products. For example, if the product is fragile or delicate, it may be necessary to use specialized machinery to ensure that it is not damaged during the packaging process.

Production speed

Depending on the volume of production, it may be necessary to choose a machine that can handle a higher workload or can run at a higher speed.

Cost

As with any investment, it is important to consider the cost of the machinery. This includes not only the initial cost of the machine but also the long-term running and maintenance costs.

Durability and reliability

It is important to choose a machine that is durable and reliable to ensure that it will meet the demands of production.

9. Innovations in packaging machinery

The packaging machinery industry is constantly evolving, with new innovations and technologies emerging regularly. Recent trends include the increasing automation of packaging processes, the adoption of robotics and artificial intelligence, data collection, and the search for more sustainable and environmentally friendly solutions.

These trends are driving the development of new packaging solutions that are more efficient, versatile, and able to adapt to the changing demands of consumers and business needs.

10. Conclusion

Packaging machinery plays a key role in the production and distribution of products. Whether you are packaging food, pharmaceuticals, cosmetics, or any other product, it is vital to select the right machinery for your specific needs. With a variety of options available, from product loading with pick & place robots to final palletizing, it is possible to find the perfect solution for your packaging needs.

11. Start your journey with ATP Packaging today

Choosing the right packaging machinery is a critical step in setting up your production and distribution process. At ATP Packaging, we are proud to offer a wide range of high-quality packaging machinery solutions, designed to meet a variety of packaging needs.

Our team of experts is ready to guide you through our options and help you choose the machinery that best suits your specific needs. With our industry knowledge and commitment to excellence, we can provide you with the tools you need to streamline your packaging process and take your business to the next level.

No matter what your packaging challenge is, we are here to help you overcome it. Contact us today to find out how ATP Packaging machinery can transform your production process. Do not wait any longer, make the move and ensure the efficiency and quality of your packaging line with ATP Packaging.